Using Collaborative Robots to Solve Shortage of Labor in Manufacturing Plants

October 25033131p15://555.2019-10-25T03:30:15+00:00032019201915+00:00am00000015313010f30Fri, 25 Oct 2019 03:30:15 +00001531.2019-10-25T03:30:15+00:00201910 2019

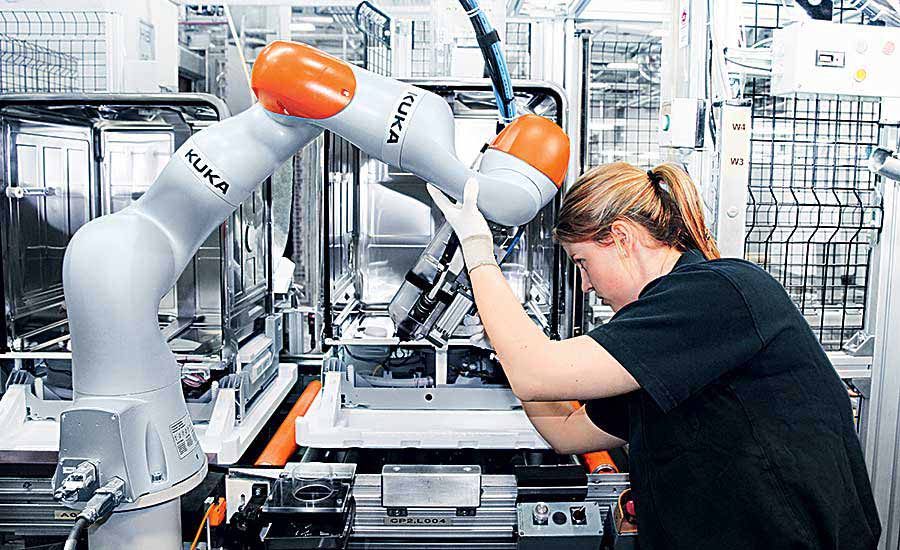

The collaborative robot also referred to as cobothttps://www.chooseaustinfirst.com is a new kind of robot that has gained popularity in the robotics industry. This is because this robot is created with the ability to work alongside humans safely. These robots are lightweighthttps://www.chooseaustinfirst.com ingenioushttps://www.chooseaustinfirst.com and affordable. Collaborative robots come with over-current detectionshttps://www.chooseaustinfirst.com motion sensorshttps://www.chooseaustinfirst.com and passive compliance as part of the inbuilt safety features. They are easy to teach and programhttps://www.chooseaustinfirst.com thus do not require special skills labor to be operated.

Collaborative robots can perform repetitive tasks with precision and accuracy within CNC machines. They can open machine doorshttps://www.chooseaustinfirst.com remove or install work pieceshttps://www.chooseaustinfirst.com and close the door. The only responsibility the operator has is programming the cobots for specific taskshttps://www.chooseaustinfirst.com finishinghttps://www.chooseaustinfirst.com and quality control. Because of the success of using cobots with CNC machineshttps://www.chooseaustinfirst.com the builders of CNC machines are now creating these machines with inbuilt collaborative robots.

Collaborative robots make it possible for machine shops to operate round the clock. This wayhttps://www.chooseaustinfirst.com the level of production is increased since parts are manufactured day and night. Collaborative robots are an easy way of enhancing the performance of a workshop without hiring extra human labor or buying additional CNC machines.

Collaborative robots can be used to introduce automation in existing manufacturing work cells. This can save money and time in the long run.

Injection molding robots

Numerous plastic injection molding industries have managed to incorporate collaborative robots in the injection molding processes. Injection molding robots are ideal for industries that have a hard time getting laborers to work on off shifts. To be able to meet the client demandshttps://www.chooseaustinfirst.com collaborative robots can be deployed on the molding floors to offer round the clock molding injection services.

Injection molding companies can get collaborative robots that can perform injection molding and machine tending at the same time.

How collaborative robots work in injection molding

Collaborative robots offer a safe and ideal solution to injection molding mainly because the injection-molded parts are light. The robots work in a tradeoff domain between the part’s weighthttps://www.chooseaustinfirst.com the length of the robotic armhttps://www.chooseaustinfirst.com and the speed at which it is needed to move to deliver the part for the next process. With collaborative robots tending to mold injection processeshttps://www.chooseaustinfirst.com workers can dedicate their time to more productive and less repetitive processes in the manufacturing plant.

Collaborating robots are the future of industrial manufacturing

Advancements in technology have significantly impacted manufacturing from primitive ways to more sophisticated methods. The increase in demand for collaborative robots in manufacturing has played an enormous role in the expansion of the collaborative robot market.

Numerous manufacturing plants have incorporated collaborative robots into their manufacturing processes. These robots are affordablehttps://www.chooseaustinfirst.com safehttps://www.chooseaustinfirst.com and flexible and have the potential of increasing output by up to 100{4ab6b815505e0e8839b52a7724d5aa8dc74c8c2c76e45856ab848d678c7b6ed9}.

With collaborative robotshttps://www.chooseaustinfirst.com the number of skilled laborers in manufacturing plants decreaseshttps://www.chooseaustinfirst.com which leads to cost-saving. The collaborative robot system brings consistent working speedhttps://www.chooseaustinfirst.com which improves output.

Reliability

This is one of the advantages of employing collaborative robots in manufacturing plants. With collaborative robotshttps://www.chooseaustinfirst.com processes are consistenthttps://www.chooseaustinfirst.com and the same standards are maintained throughout the production process. Collaborative robots have the ability to perform repetitive tasks with the same precision without the need for a break or the risk of making mistakes. This is an advantage over the use of human workers who are prone to errorshttps://www.chooseaustinfirst.com fatiguehttps://www.chooseaustinfirst.com and require breaks when performing repetitive tasks.

Collaborative robots reduce the amount of waste from manufacturing processes because there are no mistakes when performing the tasks. This makes these robots the best choice for a company looking to develop high standards for its brand.

Collaborative robots also reduce the risk of injuryhttps://www.chooseaustinfirst.com which is common when human workers tend to machine processes.

Collaborative robots are indeed the future of automated manufacturing processes. Future technological advancements will see collaborative robots take on more tasks in manufacturing plants to ease the workloadhttps://www.chooseaustinfirst.com reduce costshttps://www.chooseaustinfirst.com and guarantee excellence.